Humidity at Work: How Moisture Turns Cured Films Into Sticky Failures

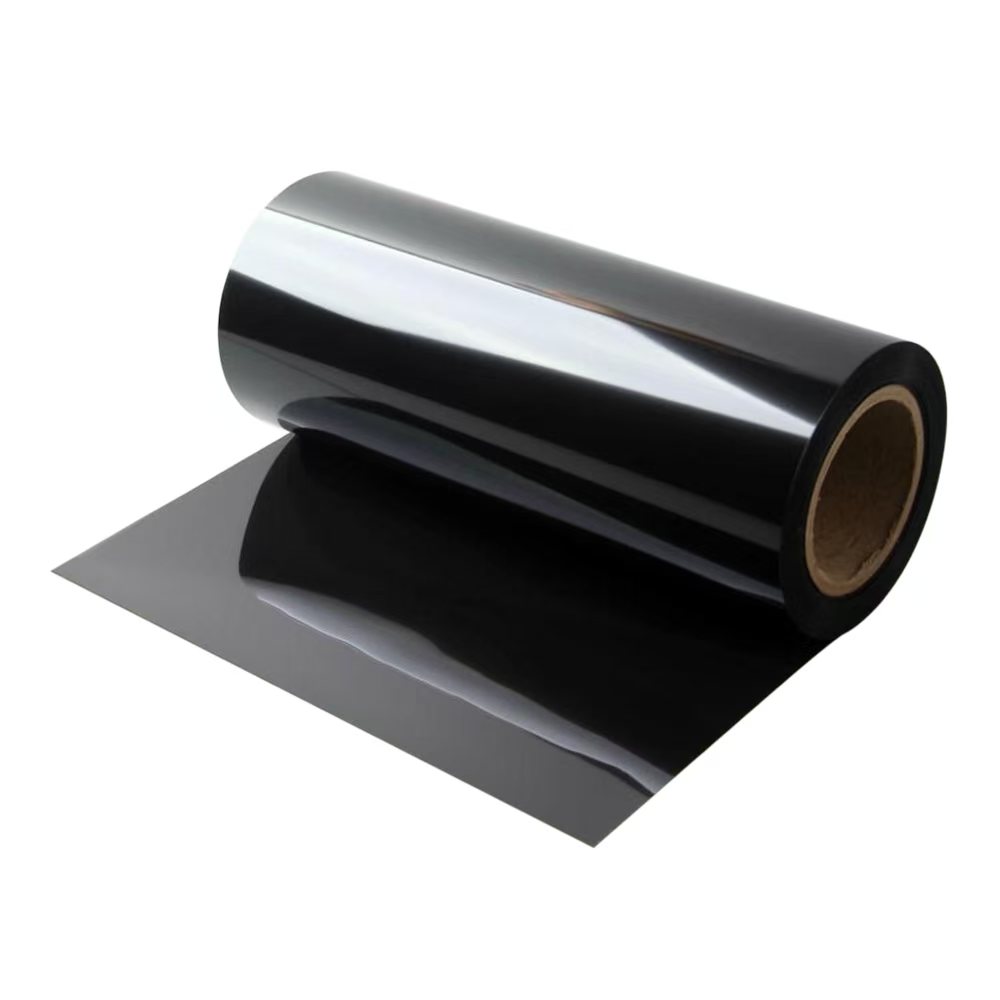

A roll of coated film may leave the factory in perfect condition—smooth, dry, well-cured. But by the time it arrives at the customer’s site, it’s fused at the edges, difficult to unwind, or fully blocked. One silent culprit is at play: humidity.

This article explores how humidity, in combination with other storage conditions such as pallet pressure, causes blocking during storage—even when the coating process was executed flawlessly.

1. Humidity Is Not Just Water in the Air

In industrial environments, humidity refers to the moisture content in the air (relative humidity or RH). When RH rises above 55%, especially in warm conditions, coated films begin to interact with moisture in damaging ways:

- Hydrophilic coatings absorb water, softening their surface

- Micro-condensation at roll interfaces adds temporary tack

- Moisture plasticization alters polymer structure, reducing hardness

These effects are subtle at first—but deadly when combined with storage conditions that keep films compressed or warm.

2. The Moisture Absorption Mechanism

Not all films are equally sensitive to humidity, but many coatings, especially water-based systems, absorb moisture readily:

- Acrylic dispersions can soften by over 40% at RH > 70%

- Polyurethane dispersions swell, increasing surface tack

- Coatings with residual hydrophilic groups become semi-adhesive under humidity cycling

For instance, a polyolefin film coated with water-based primer was stable at 23°C/50% RH. When exposed to 75% RH for 48 hours, its COF (Coefficient of Friction) increased by 50%—enough to trigger blocking under mild pallet pressure.

3. Where Humidity Builds Up: Inside the Roll

Humidity damage isn’t just ambient. It can accumulate inside the roll:

- Tightly wound rolls trap air and moisture

- Warm air holds more water—leading to internal RH spikes

- Condensation can form between layers during temperature cycling

This means that even if the warehouse appears dry, the storage conditions within a wrapped pallet may be vastly different—especially without ventilation or when rolls are shrink-wrapped.

4. Humidity + Pallet Pressure = Blocking

Pallet pressure is the force exerted by stacking rolls. When films are exposed to high RH and compressed by roll weight, blocking risks increase dramatically:

- Humidified layers soften and become tacky

- Compressed surfaces fuse over time

- Blocking appears after 2–3 days in storage, not immediately

A common failure case: films stored on the lower levels of tall pallets (5–6 layers) show more severe blocking than those at the top—because they faced the most pressure under humidity.

5. Humidity During Shipping

Transit is a major source of uncontrolled humidity exposure:

- Closed trucks without climate control reach 85% RH easily

- Long-haul containers crossing humid regions accumulate condensation

- Sealed pallets trap evaporating moisture

This explains why many blocking issues only appear after shipping, even if warehouse storage was optimal.

6. How to Control Humidity in Film Storage

To prevent humidity-driven blocking, best practices include:

- Store films at RH below 55%, ideally with temperature control (20–25°C)

- Use ventilated pallets and avoid airtight wrapping

- Include humidity indicators in large roll packages

- Limit stacking height to reduce combined RH + pallet pressure effects

- Allow rolls to acclimate before final packaging (24–48h flat aging)

- Use desiccants for sensitive films or long-distance shipping

7. Quality Control: Simulate the Real Risks

Standard QA often ignores storage simulation. Implement:

- Accelerated humidity aging tests (e.g., 60% RH @ 30°C for 72h)

- Blocking under load: simulate pressure in real pallets

- Post-shipping COF tests to detect surface tack changes

These tests better reflect the impact of storage conditions, especially humidity, than in-line coating QA alone.

Summary

Humidity is one of the most underestimated threats to coated films. It acts slowly, invisibly, and often in combination with pallet pressure and poor storage conditions to cause blocking days or weeks after production.

Without climate awareness, even a perfect coating can fail in the warehouse or during transit. Managing humidity is not optional—it's critical to quality, performance, and customer satisfaction.

SEO Tags

- humidity

- storage conditions

- pallet pressure

- moisture damage in films

- RH control in packaging

- humidity blocking failure

- roll storage best practices

- film tack increase

- condensation and blocking

- warehouse humidity risk

- film fusion under load

- long-term storage QA

- blocking after shipping

- climate control logistics

- shrink wrap trap moisture

- film packaging SOP

- RH vs film softness

- stacking-induced failure

- film COF rise

- humidity absorption coating

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.