Best Practices for PET Surface Treatment in High-Resolution Printing

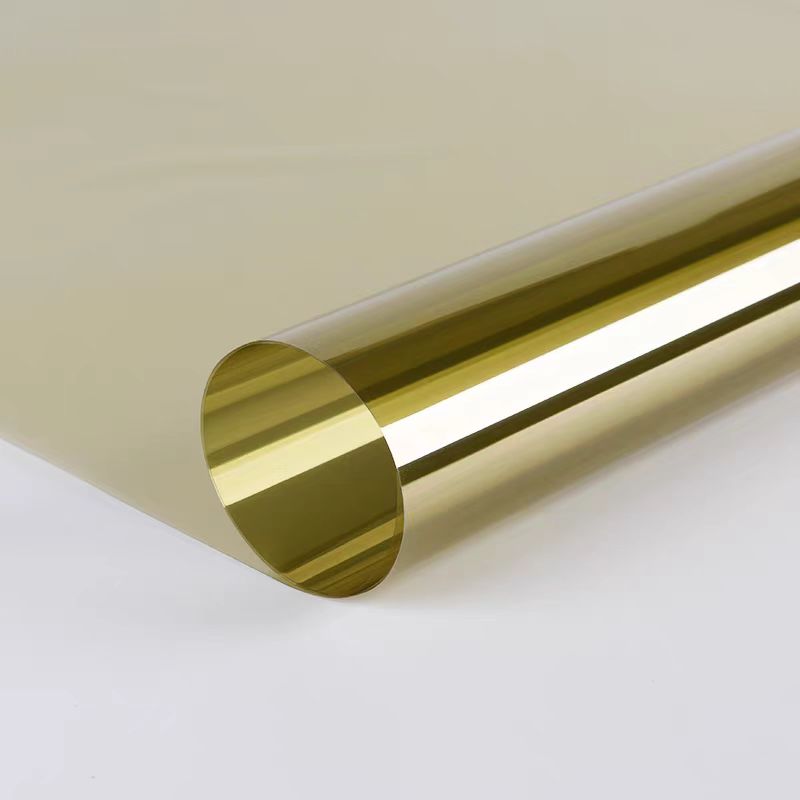

Printing on PET films requires more than just quality inks and hardware—it demands precise surface modification to enable excellent ink adhesion and print definition. One of the key enablers of this performance is PET surface treatment, which transforms low-energy PET into a reliable printable PET film. In this article, we will explore best practices for surface treatment, focusing particularly on corona treated PET film used in high-resolution printing environments.

1. PET’s Natural Surface Limitations

Polyethylene terephthalate (PET) is known for its strength, flexibility, and optical clarity, but its chemically inert and hydrophobic surface resists ink bonding. This creates challenges such as:

Ink beading or flaking

Poor color density

Unstable print durability

PET surface treatment is necessary to increase the surface energy of PET films, making them receptive to ink, coatings, and adhesives.

2. Corona Treatment: The Industry Standard

The most widely used and cost-effective method for modifying the surface of PET is corona treatment. This method involves discharging high-voltage electricity through the air onto the PET surface, creating polar groups that attract ink.

Advantages of corona treated PET film include:

Increased surface energy (typically to 38–42 dynes/cm)

Fast, inline compatibility with PET film production

Enhanced wetting for UV, solvent, and water-based inks

Proven performance across labeling, packaging, and overlay applications

Corona-treated film is widely adopted in producing printable PET film for both short-run and high-volume printing jobs.

3. Process Parameters to Control

To ensure effective PET surface treatment, printers and converters must control key parameters:

Treatment intensity: Over-treatment can degrade film; under-treatment leads to poor adhesion.

Web speed: Faster lines may require higher corona power.

Humidity & contamination: Both reduce treatment effectiveness—keep the environment clean and dry.

Routine quality checks should include:

Dyne tests (surface energy)

Adhesion tape tests

Visual inspection under magnification

High-performance printable PET film relies on maintaining these parameters consistently.

4. Handling and Storage After Treatment

Once a PET film is corona treated, its surface energy may degrade over time—a phenomenon called "aging." This is especially critical for films stored in humid or dusty environments.

Storage guidelines for corona treated PET film:

Use within 6–12 months of treatment

Keep in original sealed packaging

Avoid exposure to sunlight, heat, or ozone

Re-test surface energy before use if stored long-term

In some cases, re-treating film with corona discharge before printing may restore surface properties.

5. Ink System Selection for Treated Films

Printable PET film that has undergone corona treatment can work with a wide range of ink systems, but optimal results come from matching inks to surface energy.

Recommended inks:

UV-curable inks: Preferred for fast curing and strong adhesion

Solvent-based inks: High color density and durability

Latex/water-based inks: Require primer or dual-treatment

To ensure optimal adhesion, test each ink type with your film and press system.

6. Advanced Treatment: Dual-Side or Patterned Corona

Some advanced printing applications require both sides of the film to be printable or one side to be coated differently.

Dual-side corona treated PET film: For double-sided printing or bonding

Patterned corona treatment: For functional areas or selective adhesion (e.g., touch panels)

These specialty PET surface treatment techniques are ideal for electronics, medical labels, and high-end display graphics.

7. Selecting a Quality Printable PET Film Supplier

The right supplier will ensure your printable PET film is treated to exacting standards.

Choose suppliers who offer:

Surface energy certificates (with dyne readings)

Application-specific coating options

Custom roll sizing and slitting

Consistent corona treated PET film across lots

A reliable supplier is critical for businesses that rely on consistent print quality and product durability.

SEO关键词使用情况(每个出现3次):

corona treated PET film

PET surface treatment

printable PET film

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.